Polarizing Optics

Beamsplitter Plates

Polarizing beamsplitter plate are often used to split or combine two perpendicular light sources based upon the state of polarization. Polarizing plate beamsplitters can be custom manufactured for large angle apertures, consistently high throughput and exceptional uniformity and contrast.

Non-polarizing beamsplitters are designed to maintain polarization, they are ideal for laser beam manipulation applications involving critical polarization control. Non-polarizing plate beamsplitters can be fabricated in various sizes and shapes, with different coatings to maintain polarization and protect against laser damage.

MOK Optics capability:

| Material | N-BK7, UVFS |

| Dimension tolerance | ±0.1mm |

| Surface quality | up to 20-10 |

| Flatness | up to λ/8 @ 633nm |

| Beam Deviation | 1 arcmin |

| Beamsplitter coating | T/R=50/50 ±5%, T+R>85% |

| /Ts-Tp/<10%, /Rs-Rp/<10% |

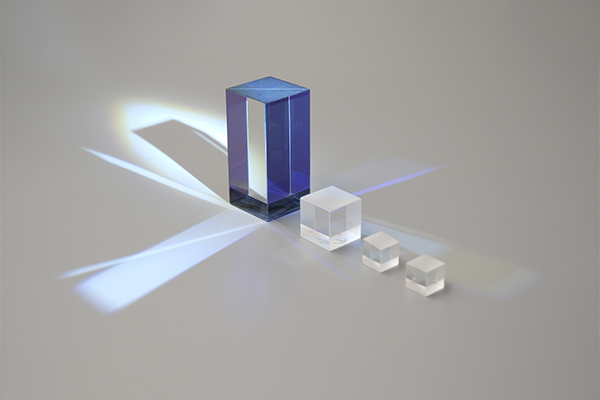

Beamsplitter Cubes

Beamsplitter cube is a prism cemented by two right angle prisms. Compare with beamsplitter plate, beamsplitter cube has the advantages:

- Identical path lengths for both the reflected and the transmitted beams

- The transmitted beam is neither displaced nor deflected.

- Stable and compact.

- Easy operation.

- Easy for mounting/aligning

Polarization beamsplitter cubes are optical components widely used in various high-energy laser systems, optical instruments, and scientific applications. These cubes are specifically designed to split an incoming beam of light into two orthogonally polarized beams, typically transmitting p polarization, while reflecting the s-polarization. This makes them essential in applications requiring precise polarization management, high contrast, and efficient energy handling.

MOK Optics capability:

| Material | N-BK7, UVFS |

| Dimension tolerance | ±0.1mm |

| Surface quality | up to 20-10 |

| Flatness | up to λ/8 @ 633nm |

| Extinction Ratio | up to 1000: 1 |

| Beam Deviation | 1 arcmin |

| Polarizing Beamsplitter Coating | Principal Transmitacne: Tp>95%, Ts<1% |

| Principal Reflectance: Rs>99%, Rp<5% |

Non-Polarizing Beamsplitter Cube is designed to divide an incident beam into two beams of similar energy that do not change their polarization state. Unlike conventional polarization beam splitters, non-polarization beam splitters are not sensitive to the polarization of light, making them suitable for applications where the polarization state of the beam needs to be kept constant.

MOK Optics Capability:

| Material: | N-BK7, UVFS |

| Dimension tolerance | ±0.1mm |

| Surface quality | up to 20-10 |

| Flatness | up to λ/8 @ 633nm |

| Beam Deviation | 1 arcmin |

| Non-polarizing Beamsplitter Coating | T/R=50/50 ±5%, T+R>85% |

| /Ts-Tp/<10%, /Rs-Rp/<10% |

Waveplates / Retarders

Waveplates are made from birefringent materials, most commonly crystal quartz. Birefringent materials have slightly different indices of refraction for light polarized in different orientations. As such, they separate incident unpolarized light into its parallel and orthogonal components

Typical retardation:

- λ/2 waveplate (Half waveplate)

- λ/4 waveplate (Quarter waveplate)

MOK Optics produces various types of waveplates to meet the needs of customers for different applications

Low order waveplate (Multiple order waveplate) means the retardance of a light path will undergo a certain number of full wavelength shifts in addition to the fractional design retardance. The thickness of multi order waveplate is always around 0.5mm. Compared with zero order waveplate, Low-order waveplate is more sensitive to wavelength and temperature changes. However, they are less expensive and widely used in many applications where the increased sensitivities are not critical.

Features:

- Low temperature bandwidth

- Low wavelength bandwidth

- High damage threshold

- Low cost

Achromatic waveplate is similar to zero order waveplate except that the two plates are made from different birefringent crystals. Since the dispersion of the birefringence of two materials is different, it is possible to specify the retardation values at a broad wavelength range. So, the retardation will be less sensitive to wavelength change. In other words, it can be used at a broadband wavelength range(400-700nm, 700-1200nm, 1100-2000nm).

Features:

- Good temperature banwidth

- Very broad wavelength bandwidth

- Cemented and air spaced available

Cemented zero order waveplate is constructed by two quartz plates with their fast axis crossed, the two plates are cemented by UV epoxy. The difference in thickness between the two plates determines the retardation. Zero order waveplates offer a substantially lower dependence on temperature and wavelength change than multi order waveplates.

Features:

- Cemented by Epoxy

- Thickness 1.5~2mm

- Double Retardation Plates

- Broad Spectral Bandwidth

- Wide Temperature bandwidth

- AR coated and Mounted

Air spaced zero order waveplate is constructed by two quartz plates installed in a mount, to form a air gap between the two quartz plates. The difference in thickness between the two plates determines the retardation. Zero order waveplates offer a substantially lower dependence on temperature and wavelength change than multiorder waveplates.

Features:

- Mounted, no glue

- Broad Spectral Bandwidth

- Wide Temperature bandwidth

- Hight Damage Threshold

Optical Contacted zero order waveplate is constructed by two quartz plates with their fast axis crossed, the two plates are constructed by optically contacted method, the optical path is epoxy free. The difference in thickness between the two plates determines the retardation. Zero order waveplates offer a substantially lower dependence on temperature and wavelength change than multi order waveplates.

Features:

- Optical Contacted,no glue

- Double Retardation Plates

- Broad Spectral Bandwidth

- Wide Temperature bandwidth

- Hight Damage Threshold

True zero-order waveplate means the thickness of waveplate is very thin which make it excellent under the conditions of wide scope of application temperature, wide application wavelength and big incident angle. Therefore, it’s an excelent choice for high accurate applications

Cemented true zero order waveplate

- Cemented by glue

- Good temperature bandwidth

- Wide wavelength bandwidth

- Moderate damage threshold

- Excellent retardation performance

Single plate true zero order waveplate

- Good temperature bandwidth

- Wide wavelength bandwidth

- High damage threshold

- Only 1310nm, 1550nm available

MOK Optical capability:

| Material | Quartz, MgF2 |

| Dimension tolerance | ±0.05mm |

| Retardation | 1/2λ, 1/4λ |

| Retardation Tolerance | λ/100 |

| Surface quality | 20/10 |

| Wavefront Distortion | λ/10@633nm |

| AR coating | Upon custom design |